Next Generation Container Port | 2014.03

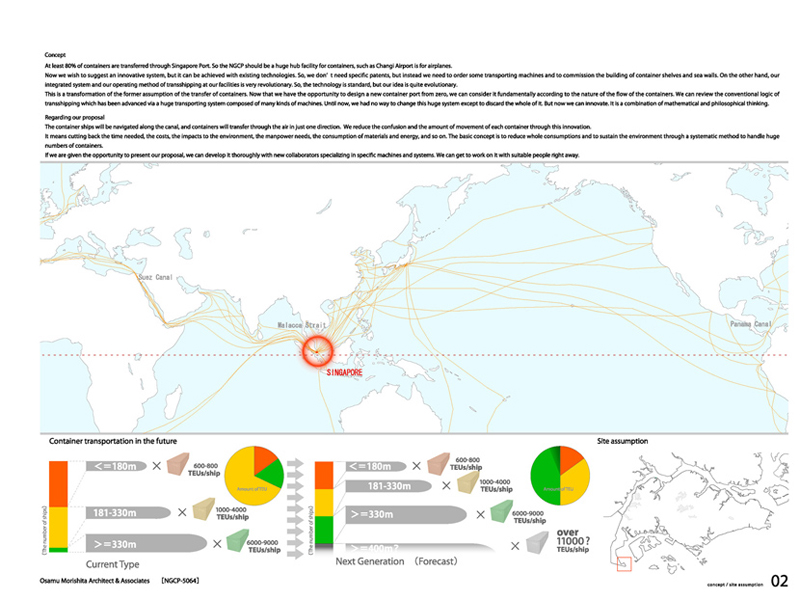

Site Location: Singapore. Singapore Building Use: Container Port Awards 2014 MIPIM Architectural Review Future Projects Awards in Cannes Sustainability Prize Webpage Winners 2014 The Telegraph BBC

Introduction

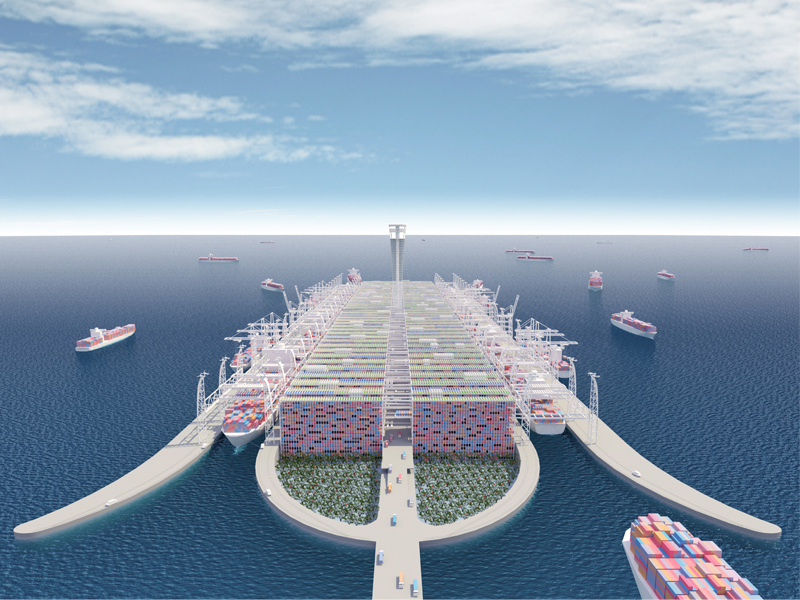

At least 80% of containers are transferred through Singapore Port. So the NGCP should be a huge hub facility

for containers, such as Changi Airport is for airplanes.

Now we wish to suggest an innovative system, but it can be achieved with existing technologies. So, we don't

need specific patents, but instead we need to order some transporting machines and to commission the

building of container shelves and sea walls. On the other hand, our integrated system and our operating

method of transshipping at our facilities is very revolutionary. So, the technology is standard, but our

idea is quite evolutionary.

This is a transformation of the former assumption of the transfer of containers. Now that we have the

opportunity to design a new container port from zero, we can consider it fundamentally according to the

nature of the flow of the containers. We can review the conventional logic of transshipping which has

been advanced via a huge transporting system composed of many kinds of machines. Until now, we had no

way to change this huge system except to discard the whole of it. But now we can innovate. It is a

combination of mathematical and philosophical thinking.

Regarding our proposal The container ships will be navigated along the canal, and containers will transfer

through the air in just one direction. We reduce the confusion and the amount of movement of each container

through this innovation.

It means cutting back the time needed, the costs, the impacts to the environment, the manpower needs, the

consumption of materials and energy, and so on. The basic concept is to reduce whole consumptions and to

sustain the environment through a systematic method to handle huge numbers of containers.

If we are given the opportunity to present our proposal, we can develop it thoroughly with new collaborators

specializing in specific machines and systems. We can get to work on it with suitable people right away.

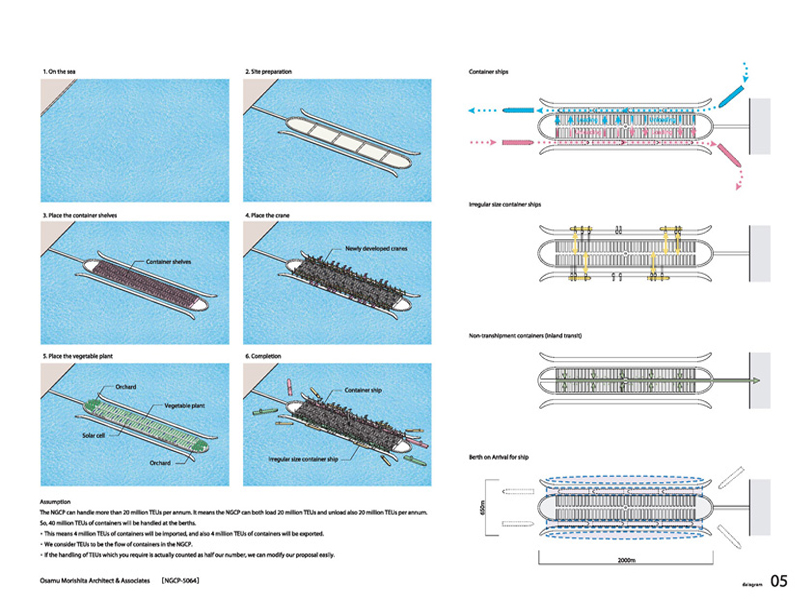

Assumption

The NGCP can handle more than 20 million TEUs per annum. It means the NGCP can both load 20 million TEUs and

unload also 20 million TEUs per annum. So, 40 million TEUs of containers will be handled at the berths.

・This means 4 million TEUs of containers will be imported, and also 4 million TEUs of containers will be exported.

・We consider TEUs to be the flow of containers in the NGCP.

・If the handling of TEUs which you require is actually counted as half our number, we can modify our proposal easily.

Think about Location

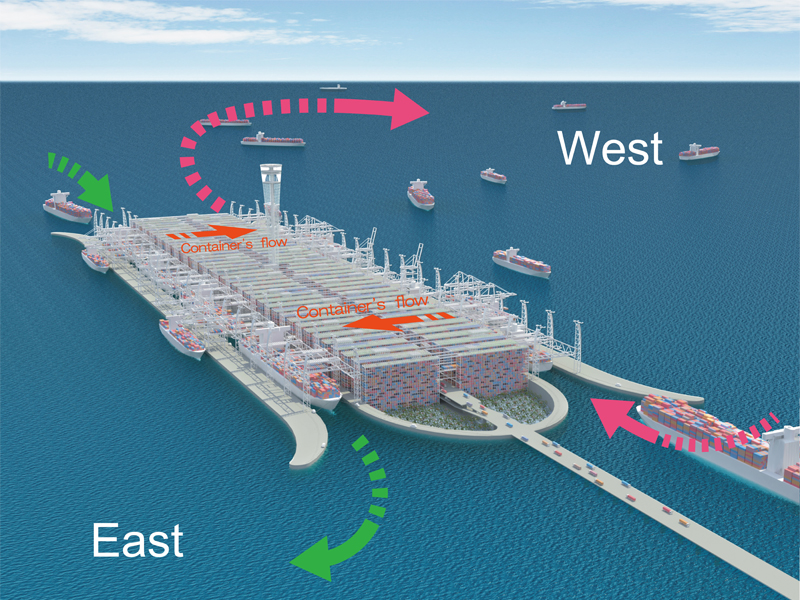

Globally, there are two main directions of container flows. One is from the West to the East, the other one is the

opposite way. Now we are considering the flow of containers through the port. We tried to fit it to the actual

movement of containers around the globe. There are the basic movements of cargos from the West going to the East,

and cargos from the East flowing to the West. We adopted this simple movement on the space of the container yard.

So there are just two directions of the large movements through the container yard, except between the NGCP and

Singapore Island themselves. Each flow is just one way from a berth for unloading to a berth for loading

(and from a berth to a semi-truck trailer). The flows are so clear this way. The movement is just one way, and a

simple movement at that. There will not be lost time due to confusion.

Electricity generated by Gas Engines

The all systems of our proposal will be operated by the electricity generated by gas engines. The generation efficiency

is about 49 %. And our systems run very efficiently, so total efficiency is so superior to existing systems.

Discussion on Key Design Aspect

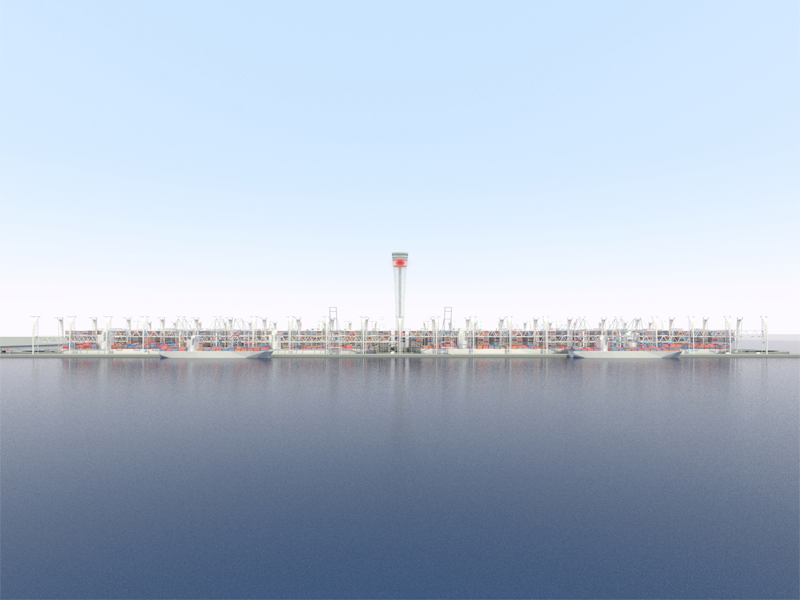

・Land/Huge Vessel

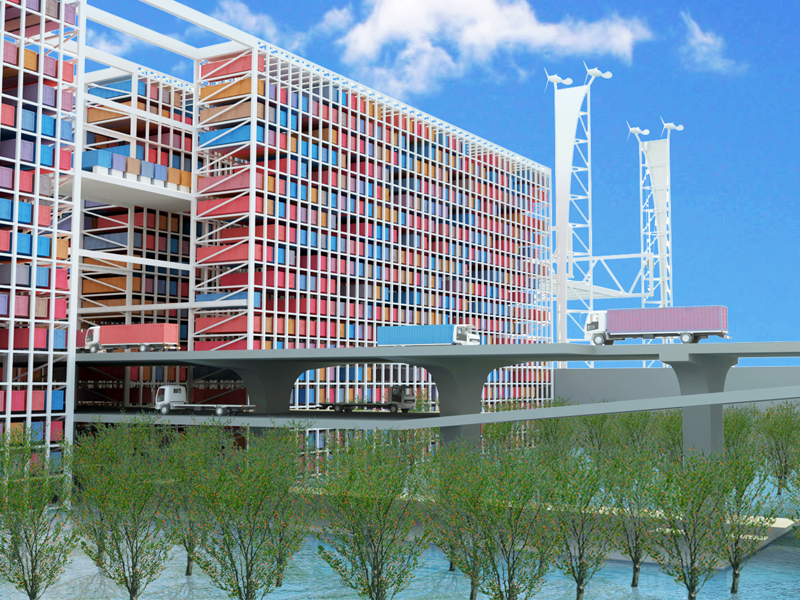

The land for the NGCP should not be reclaimed with earth and sand from the hinterland, but should be constructed by

being surrounded with steel cylindrical caissons that are filled with a mix of mud dredged up from the sea and cement.

The caissons will be aligned in a continuous line in the shape of huge ships, forming a seawall, and the reinforced

concrete will be poured inside this to strengthen the seawall and the bottom of the huge ship. Under the bottom, piles

are also driven. The structure will be a waterproofed Huge Vessel, but it also has big partitions to divide the vessel

into several sections. So, even if sea water comes through a seawall, the sections will prevent the water from spreading

and filling the whole vessel. In addition to this feature, there are drain pumps in each section. We just pump the water

out of the Huge Vessel.

The land necessary already exists under the Sea, So, We need not transport earth and sand. And the outriggers are also

constructed on the caissons. Furthermore, we are trying to reduce the area of the Huge Vessel by adopting an innovative

system to handle the containers. We need just 85 hectares of land for the Huge Vessel. It is the most ecological way to

reduce the many kinds of quantities of materials, costs, etc. If we reduce the area, the movement-length of each container

will be reduced as well.Our innovative method will contribute to lower costs, to faster delivery and to sustaining the

environment.

A similar caisson construction method is “The Sheet Piling Cell Construction Method” by Nippon Steel & Sumitomo Metal.

But there are several kinds of similar construction methods. So, we can choose any method, as long as the quality and a

reasonable cost is guaranteed.

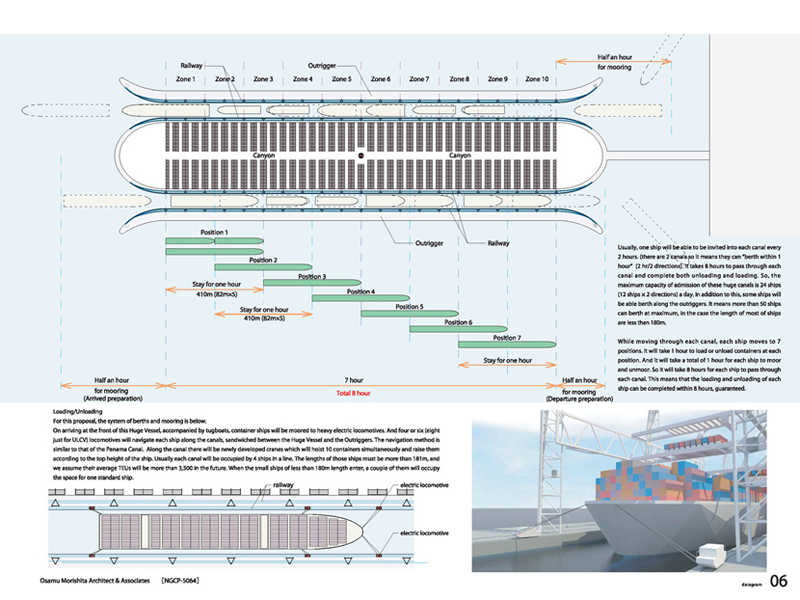

Loading/Unloading

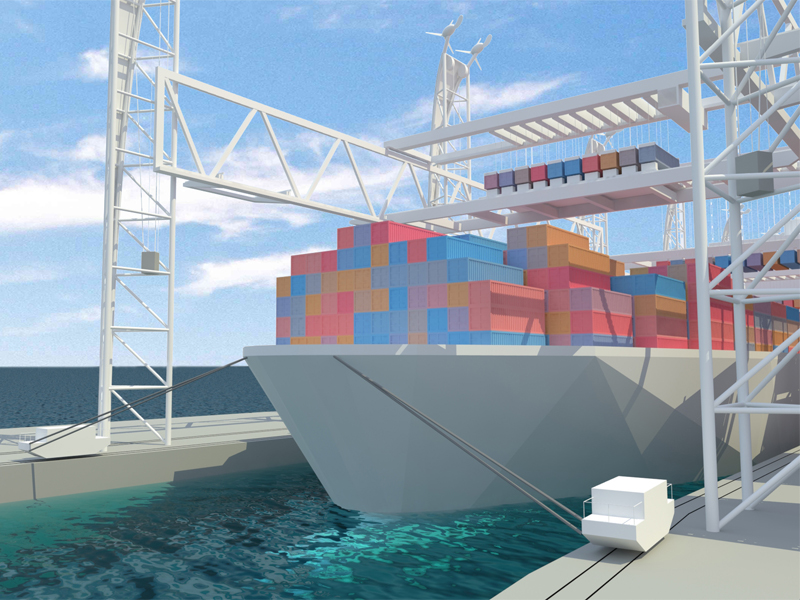

For this proposal, the system of berths and mooring is below. On arriving at the front of this Huge Vessel, accompanied by

tugboats, container ships will be moored to heavy electric locomotives. And four or six (eight just for ULCV) locomotives

will navigate each ship along the canals, sandwiched between the Huge Vessel and the Outriggers. The navigation method is

similar to that of the Panama Canal. Along the canal there will be newly developed cranes which will hoist 10 containers

simultaneously and raise them according to the top height of the ship. Usually each canal will be occupied by 4 ships in a

line. The lengths of those ships must be more than 181m, and we assume their average TEUs will be more than 3,500 in the

future. When the small ships of less than 180m length enter, a couple of them will occupy the space for one standard ship.

In addition, there are so-called gantry cranes on the quays along the sea side of the Outriggers. They will be for the

irregular size ships (for urgent or just loading/unloading portions of containers).

Usually, one ship will be able to be invited into each canal every 2 hours. (there are 2 canals so it means they can

“berth within 1 hour”(2 hr/2 directions). It takes 8 hours to pass through each canal and complete both unloading and

loading. So, the maximum capacity of admission of these huge canals is 24 ships (12 ships × 2 directions) a day. In addition

to this, some ships will be able berth along the outriggers. It means more than 50 ships can berth at maximum, in the case

the length of most of ships are less than 180m.

While moving through each canal, each ship moves to 7 positions. It will take 1 hour to load or unload containers at each

position. And it will take a total of 1 hour for each ship to moor and unmoor. So it will take 8 hours for each ship to pass

through each canal. This means that the loading and unloading of each ship can be completed within 8 hours, guaranteed.

By the way, if necessary, we can shorten time even more because we have incorporated large margins for flexibility.

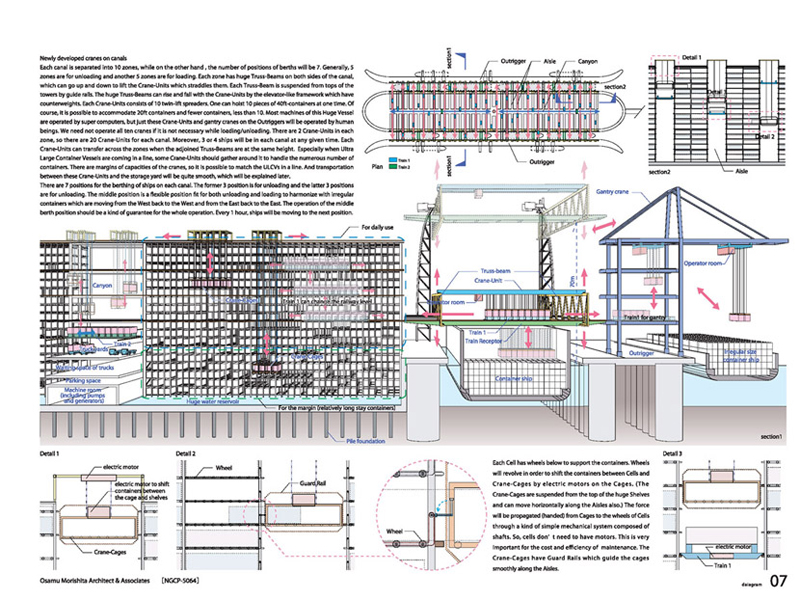

Newly developed cranes on canals

Each canal is separated into 10 zones, while on the other hand , the number of positions of berths will be 7. Generally,

5 zones are for unloading and another 5 zones are for loading. Each zone has huge Truss-Beams on both sides of the canal,

which can go up and down to lift the Crane-Units which straddles them. Each Truss-Beam is suspended from tops of the towers

by guide rails. The huge Truss-Beams can rise and fall with the Crane-Units by the elevator-like framework which have

counterweights. Each Crane-Units consists of 10 twin-lift spreaders. One can hoist 10 pieces of 40ft-containers at one time.

Of course, it is possible to accommodate 20ft containers and fewer containers, less than 10. Most machines of this Huge

Vessel are operated by super computers, but just these Crane-Units and gantry cranes on the Outriggers will be operated by

human beings. We need not operate all ten cranes if it is not necessary while loading/unloading. There are 2 Crane-Units

in each zone, so there are 20 Crane-Units for each canal. Moreover, 3 or 4 ships will be in each canal at any given time.

Each Crane-Units can transfer across the zones when the adjoined Truss-Beams are at the same height. Especially when Ultra

Large Container Vessels are coming in a line, some Crane-Units should gather around it to handle the numerous number of

containers. There are margins of capacities of the cranes, so it is possible to match the ULCVs in a line.

And transportation between these Crane-Units and the storage yard will be quite smooth, which will be explained later.

There are 7 positions for the berthing of ships on each canal. The former 3 position is for unloading and the latter 3

positions are for unloading. The middle position is a flexible position fit for both unloading and loading to harmonize

with irregular containers which are moving from the West back to the West and from the East back to the East. The operation

of the middle berth position should be a kind of guarantee for the whole operation. Every 1 hour, ships will be moving to

the next position.

Theoretically this system can operate containers at the below maximum. The assumption is that cranes can handle containers

30 times per 1 hour.

10 (cranes/unit)×30 (times/h)×2 (units/zone)×10 (zones)÷(4+3)/2 (ships) ×1 (hour/position)×7/2 (positions )

=6,000 (pieces of 40ft-containers)

=12,000 TEUs (per ships) + α

And each canal can handle the ULCVs, whose TEUs are more than 15,000, by gathering Crane-Units around them.

One day’s maximum number, theoretically.

12,000×12(ships)×2(canals)

=288,000TEU/day (flows of containers)

=576,000TEU/day (numbers on berths)

So, it can be guaranteed for the rows consisting of only large containers.

Usually the row will be composed of several sized vessels, so there sufficient safety margin for the operations is built in.

Theoretically, we can reduce the time it takes ships to pass through each canal even more.

Storage and Retrieval

The storage yard will consist of huge steel Shelves for containers, and they will have more than 110 thousands Cells for

40ft containers. The number of Cells was decided on the assumption based on Section 3.2 of NGCP Challenge document.

Two of the 20ft containers can also be held in each Cell.

20milion/365day/2TEU×4days≒110,000cells

means

more than 220,000 TEU

Actual number

40 rows×2 (W.E.blocks)×18 stairs×40×2 (lines)

=115,200 cells

There is some space around the Tower without cells.

The total number of Cells = 115,000 cells

=230,000 TEU

Each Cell has wheels below to support the containers. Wheels will revolve in order to shift the containers between Cells

and Crane-Cages by electric motors on the Cages. (The Crane-Cages are suspended from the top of the huge Shelves and can

move horizontally along the Aisles also.) The force will be propagated (handed) from Cages to the wheels of Cells through

a kind of simple mechanical system composed of shafts. So, cells don’t need to have motors. This is very important for

the cost and efficiency of maintenance. The Crane-Cages have Guard Rails which guide the cages smoothly along the Aisles.

Yard/Quay Transfer

We propose an innovative transfer system between Crane-Units along each canal and storage yard. There will be a kind of

train which runs on railways in each Aisle between Shelves. Train 1 carries 10 containers at one time. The Crane-Units

straddling Truss-Beams create openings between containers before they put containers on Train 1 to fit the Shelves spans.

There are 3 levels of railways on each Aisle, one of which is chosen for use by the height of Truss-Beams on canals.

There are movable railways units (the Train Receptors) on the Truss-Beams to fit the position of the active Aisle and

Crane-Units. So, the number of these movable railways units (the Train Receptors) on each canal is 20. Train 1 system

runs smoothly, and it chooses the distance of operation by the destination of the containers. The whole flow of Train

1 will be controlled by the super computers.

After passing through Train 1, containers will be hoisted up by the Crane-Cages mentioned earlier. In each Aisle,

there are 10 pieces of the Crane-Cages, which can hoist a 40ft container or two 20ft containers. Sometimes each crane

moves separately, and sometimes all 10 cranes move together to carry 10 containers. Their movements depend on the position

of containers toward Cells in the huge storage Shelves. The operations of these cranes are also controlled by the super

computers. The super computers will also estimate the most efficient movement and position of each container from huge

amounts of information.

Gate Clearance

First we have to define the number of non-transshipment containers.

20 million/365 day×20 %≒11,000 TEU

If we assume that 50% of total number of containers is 20ft containers, we need the number of below trucks.

11,000 (TEU)×1/3+11,000 (TEU)×2/3÷2

=7,333 trucks for import and export each

7,333/24 (h)/60 (min)≒5 trucks/minutes

There will be a wide passage for the semi-trucks in the center of the Huge Vessel. We call it the Canyon. On the Canyon,

containers will be placed / lifted up semi-truck trailers directly by the Crane-Cages in the Aisles. There are many truck

yards for these operations along the Canyon, so everything runs very smoothly. The Huge Vessel is connected to the

hinterland with a vast bridge. So, there is no bottleneck at the gate.

Containers from the West to the West and from the East to the East

A few containers will move from the West to the West and from the East to the East. For those containers which flow in an

irregular fashion there are Transporters which move across the shelves rows above the central way for trucks. Now we call

this the Train 2 system. Each Train 2 unit will work on the southern and northern areas divided by the Tower. They do not

need to move across the Tower area. If they move across the tower, it would cause confusion in the container-flows and

force the abandonment of the concept. So, intentionally we prevent the transporters from crossing the. Tower

Labour Productivity

The huge system of NGCP will be operated by supercomputers for the most part. For just those operations which need sensitive

adjustment, human beings will control the machines especially the cranes when they pick up and release containers on ships

and semi-truck trailers, and will operate the heavy electric locomotives which will guide the ships. So, the whole system

will run with relatively few people. The labour productivity of each person will rise to much higher than now. On the other

hand, it is important to create jobs for the national economy. And in case of an emergency, this Huge Vessel needs a number

of employees on hand. So that is why now we propose creating a new enterprise in this huge facility. That is hydroponic

cultivation on the Shelves of containers. We have a kind of Palettes which will store rain waters, and on them vegetables

will be cultivated. It rains almost every day due to squalls and we can get sufficient insolation on the equator.

The harvesting method is very easy. Gathering the Palettes and stacking them on the Crane-Cages can be done automatically.

After that they will be loaded on the semi-truck trailers and transported to food factories. Some staff will be necessary

to maintain this vegetable space. Moreover, some Palettes can be filled with solar cells to generate electricity for raising

the vegetables. We can customize Palettes according to demands.

Concerning the assumption of employees working on the Huge Vessel

For operating the 40 Crane-Units which will straddle the truss-beams above the canals, it will take 320 people. They will

work in teams for each Crane-Unit. Each team will consist of 2 operators and 6 workers on the ships. When gantry cranes on

the outriggers are necessary, they will be operated by the same teams of the Crane-Units. This means more loading/unloading

teams are not necessary for the gantry cranes, and when a gantry crane is working the closest Crane-Unit is out of service

for safety.

For mooring and unmooring, it will take 20 people. (5 people ×4 places)

For operating the heavy locomotives, it will take 136 people. There will be 68 locomotives. An average of 6 locomotives will

be necessary to guide a ship, and the maximum number of ships in each canal will be 5 during mooring/unmooring time. So, 30

locomotives will be necessary on each canal. Additionally, small ships can be safely guided by 4 locomotives and ULCVs will

need 8 locomotives. So to make the margin for the operation when each canal is full of ships, we should prepare 8 more

locomotives.

For loading/unloading on semi-truck trailers, there should be 40 teams consisting of 2 people each, totalling 80 people.

We assume that 305 containers are loaded and 305 containers are also unloaded per hour on the Canyon on average. There will

be 40 Aisles between the Shelves for containers, so in each Aisle there will be 7.6 containers each for loading and

unloading per hour in theory. Operators will control the Crane-Cage with a handy remote controller in the final phases of

approaching the trailers.

For directing, load planning and overlooking the whole system on the control Tower, 50 people will be necessary.

For security and administration, 20 people will be necessary.

For maintaining of all facilities, systems, super-computers and the hydroponic culture, 120 people will be necessary.

The gross total of necessary employees is below. (320+20+136+80+50+20+120)×24h/8h×7day/5.25day

=2,984 people

Number of labour Hours per year per TEU is

(320+20+136+80+50+20+120)*24*365/20millionTEU

=6,534,960 / 20,000,000

=0.327hours/year TEU (flows of containers)

=0.1635hours/year TEU (numbers on berths)

The Tower

At the center of this Huge Vessel there is a Tower for the control room, room for super-computers which operate all machineries,

and an observation room for visitors. From the control room the staff will surveys the ships and all operations on the Huge

Vessel. At the top of the tower is a heliport for emergencies.

Land Use

Mainly the land will be the dry area which will be surrounded by the seawall. The huge Shelves for containers will occupy most

of the Huge Vessel, but in the center of it there will be a broad passage for the semi-truck trailers which will load and

unload containers. Under the broad passage there will be parking lots and machine rooms including pumps and generators.

All electric power consumed on the Huge Vessel will be created by the generators, wind turbines and solar cells. The generators’

fuel will come from tankers or LNG underground storage which is now under construction offshore, and come directly through pipes.

Wind turbines will be fixed to the tops of the towers from which the Truss-Beams will be suspended. And the solar cells will

be set up on the top of the Shelves according to the demand for electricity to cultivate vegetables and so on. We propose that

the top of the Shelves should be an area used for cultivation. And at the forward sections of the Huge Vessel will be hydroponic

orchards. In these orchards acerola will be cultivated in the ponds of reserved rain water. The Huge Vessel will be a huge water

reservoir. At the bottom of the vessel, rain water will be gathered. The depth of the water pond will be about 50 cm, and there

will be filtration equipment in the machine room. The purified water will be used for ships and some facilities on the Huge

Vessel and sent to hinterland.

Environ mental Protection

Future vision

This Huge Vessel is connected to the hinterland by a bridge. But this will be desighned as a large independent facility. As we

consider the fact that most containers are just transshipped through Singapore, in the future Singaporeans can create another

Huge Vessel which will be just for transshipping offshore and the number of Huge Vessels will continue to increase, if possible.

Such a hub can be extremely valuable for Singapore’s economy.

So on the Huge Vessel any system which can sustains itself should be independent. Of course they will need fuels and other things

from outside to maintain the facilities and employees, but they do not need to connect any lines to the hinterland. In that sense

we have designed it as a circular environment that uses energy efficiently, requiring fewer resources.

As mentioning in earlier section, electricity and water will be supplied on the vessel via its own systems. And to sustain the

environment, we have thought about utilizing natural energy (renewable energy). In this case we propose to adopt wind turbines,

solar cells, rainwater reservoirs and the system of hydroponic agriculture. This system of hydroponic agriculture is the idea

of turning the solar energy into vegetables. Fresh vegetables can be harvested from the nearby farm, reducing the energy needed

to transport and store foodstuffs.It will be a more efficient collector of solar energy than solar cells and so on.

The system will be like that described below.

On the top of the Shelves we put Palettes for the vegetables. The shapes will be a kind of pan whose footprint is the same as

the containers. In the pan rainwater will be captured. They can be transferred with cranes like ordinary containers. On the

Crane-Cage, they can be stacked, put on the semi-truck trailers and finally transported to a food factory in the city. The pots

of vegetables will be put on a pan in the food factory and the pan will filled with rain water quickly once on the top of Shelves,

because it rains almost every day in Singapore. Even if it does not rain on the day when a pan is set, the solar cells electricity

can take the stored rainwater from the reservoir pond or other pans by small pumps fixed to each solar cell Palette. At the same

time a little electricity is necessary to maintain the vegetable Palettes, allowing them to cultivate the vegetables quickly by

supplying liquid fertilizer and to monitor the calendar to help analyze deliveries.

And at the forward parts of the Huge Vessel will be the hydroponic orchards. On these orchards acerola will be cultivated in the

pond of stored rain water. It will be harvested in a pond, like the method for American cherries’. For fresh acerola, the distance

between the city and the orchard is very important.

The Huge Vessel will be completed without major impact on the environment. Because it does not use imported earth and sand, just

the surrounding space on the sea floor that it needs. It is a technique to literally create a huge ship. It reminds us of the Ark,

one which will survive and help sustain the environment of this globe.

Total Energy Consumption

First we assume that the NGCP handle 20 million TEUs per year. That means 20 million TEUs are unloaded and 20 million TEUs are

loaded also. So at the berths 40 million TEUs are handled in total per year.

Now we make another assumption that the movement of each containers will be very simple. On the ship it will be hoisted by the

Crane-Unit, put on Train1 and transported by Train 1 to the Huge Shelves. After that it will be hoisted by The Crane-Cage and

shifted into a “Cell” of the Huge Shelves. ( in the case of import/export, it will not be into a “Cell” but onto a semi-truck

trailer instead ). To unload it, the process will be the reverse, toward the opposite canal. The horizontal movement length of

each container will be just one way and extremely short. Additionally, it will not need to move across the berths because ships

are moving along the Huge Shelves (container storage). Ship- movement can reduce the huge consumption of energy used to transport

containers across the berths. Ships will be moving to the nearest position of each container!

The sum of each container’s vertical movement length will be similar to that of the conventional method. Standard gantry cranes

hoist containers from ships and put them on the ground, and transport them. However, we don’t handle containers on the ground but

only in the air around the container yard. So the vertical movement length of each container will be equal to the present method,

in spite of the movement of the Crane-Cage between Train1 and the Cell. Train1 can choose the most appropriate level of the railways.

There are 3 levels of height for Trains 1 to select. The most logical level will be chosen according to the vertical position of

the mass of loaded containers on the ships.

And we will never use the kind of transporters which have petrol engines and tires. Therefore, we can reduce the huge loss of energy.

The transportation will be on the water, in the air and on the railways, powered by electric motors, which will be very smooth and

efficient, without consuming much energy. We can cut back on energy lost due to attrition.

Now we estimate the total energy consumption on This Huge vessel.

・We have the data that the energy consumption of the gantry crane to handle 1TEU is 2.22kWh.

・We assume each container’s energy for vertical movement will be 2.22kWh/TEU ×2

( from berth to cell and from cell to berth)

・We assume each container’s energy for horizontal movement will be 1.56kWh/TEU

・We assume the gross of reefer container’s energy is 50 million kWh per year

・We assume the gross of energy to maintain the Huge Vessel is 15 million kWh per year.

(lighting, supercomputers, facilities about cultivation and so on)

・We assume each ship’s energy to be pulled through out each canal is 400kWh/ship.

So total consumption for containers is

20 million TEUs*(2.22*2+1.56)+50million+15million +400*12ships/day*2canals*365days

=120million+50million+15million+3.50million

=188.50million kWh/year

≒190 million kWh/year

You can imagine our proposal can reduce the consumption of energy through its innovative planning and systems. That’s why we

have the confidence to make this huge system even more efficient than the estimation above, If we get the opportunity to explain

the main ideas clearly and if the details are considered carefully, all of this is easily possible.

One more thing: we should consider using regenerative motors to balance the costs and ecological needs.

Renewable energy generated

The Huge Vessel has 168 wind turbines. The maximum developed power of each wind turbine is 10 kw. And the wind blows at 5

meters/sec on average. So each wind turbine can supply 18,000 kWh/year according to the data we have. So, total power

generation is 3 million kWh approximately.

Not only wind, but there are also solar cells. The maximum developed power of each solar cell is 140W/ ㎡.We estimate that

the annual power generation of the solar cells is 166,666 Wh / ㎡year.

So one container of solar cells on the top of the huge shelves is equivalent to the below.

166,666*2.5*12=5,000,000 Wh /year*container

=5,000 kWh / year*container

Now we assume to have installed 320 solar cell containers so the total annual power generation is 1.6 million kWh.

The total renewable energy generated is

3.0 million +1.6 million

=4.6 million kWh / year.

Total Capital Expenditure

・Sea wall of The Huge Vessel:

1.5 million (US$/m*km)*30m*4.5km

=200 million (US$)

・The foundation of outriggers:

1 million(US$/m*km)*30m*2.5km*2*2

=300 million(US$)

・The base concrete slabs and piles:

2 million (US$)*85 hectares

= 170 million (US$)

Subtotal 670million (US$)

・The Bridge:

0.005million (US$)* 36m*430m

≒80 million (US$)

・The Canyon including parking lots and machine rooms:

0.003million (US$)*36m*2050m ≒220million (US$)

・The Huge Shelves including some electric equipment for reefer containers:

0.019million (US$) 115,000cells=2185 million (US$)

・The towers of truss-beams including lifting mechanism:

1.5 million (US$)*21*4 =126 million (US$)

・The huge truss-beams, including railways:

1.5million (US$) *10*4 =60 million (US$)

・The control tower: 30 million (US$)

・The super-computer system: 20 million (US$)

・The 4 generators and facilities for maintaining the Huge Vessel: 50 million (US$)

・The wind turbines (10kw type) :

0.05 million (US$)*2*21*4=8.4 million (US$)

・The solar cells:

0.01million (US$)*320peaces=3.2 million (US$)

・The palettes for the vegetables:

0.005million (US$)*6400peaces=32 million (US$)

・The facilities for the orchards:

4 million (US$)*2=8 million (US$)

Subtotal 2822.6million (US$)

The newly developed cranes

・The Crane-Units straddling truss beams, consisting of 10 twin-lift spreaders:

5 million(US$)*20*2canals=200million (US$)

・The Train Receptors straddling Truss-Beams:

0.75 million(US$)*20*2=30 million (US$)

・The Gantry Cranes, including train rails:

5 million(US$)* 8*2=80 million (US$)

・The Trains 1 system transporting 10 containers at the maximum: 2.5 million(US$)*40=100million(US$)

・The Trains 2 system transporting 10 containers maximum: 5 million(US$)*2=10million(US$)

・The Crane-Cages along the aisles:

0.75 million(US$)*10*40=300million(US$)

・The Heavy Electric Locomotives, including railways: 2.5 million(US$)*34*2 canals = 170 million (US$)

Subtotal 890million (US$)

・For various expenses, including consultant fees, etc.:117.4 million (US$)

Total 4500 million (US$)

Operating Expenditure

Consumed electricity

Total Energy Consumption ?Renewable Energy Consumption =188.5 million kWh/year - 4.6 million kWh/year=184 million kWh/year

184 kWh/year÷365 days ÷24 hours = 21,000 kW

Above is the averaged power which the Huge Vessel will consume.

And I assume the maximum brake power of each heavy locomotive is 300kw At the navigating time of ships, 68 locomotives will

move at the same time.

So the generators may need power more than 300*68=20,400 kW momentarily.

While the all container-transporting system will be stopped during the navigating time, so we can cut off 13,700 kW

(120million kW/year÷365÷24).

Now we estimate all generators have to generate

21,000+20,400-13,700+α(margin)→27,700 + α

≧30,000 kW

We assume all generators make a kind of co-generation system compose of 4 generators of which the maximum developed power

is 7,800 kW each. According to the demand of the electricity the computer will decide how many generators should be operated.

We estimate the consumption of fuel from the fuel-efficiency and averaged operations.

21,000 kW÷7,800 kW ≒ 3 machines

Usually 3 generators should be operated.

Assumption

The Huge Vessels generators are gas engines. The generation efficiency is 49 %. The fuel is Singapore natural gas of which

calorific value is about 43.2MJ/m3=12kwh/m3 The price of natural gas is 0.2104 US$/m3

The amount of the consumption of natural gas is

184 million kWh÷( 12*0.49 ) = 31.3 million m3/year

=31.3 million*0.2104

=6.6 million US$/year

Labor cost

Many kinds of employees are working on the Huge Vessel. Of course the salaries are different according to the job. But now we

assume the average salary is 40,000 US$/year, including the costs for social securities.

40,000*2,984=119 million US$ / year

Others

Now we ignore other cost, maintenance cost, deprivation cost, Tax and so on, because there are so many ways how to estimate

them on accounting.

Incomes

We also ignore the amount of the sales of vegetables and acerolas.

Operating expenditure is

6.6+119=125.6 million US$/year

Operating expenditure per TEU (US$/TEU)

125.6 million (US$)/20million (TEU)

=6.28 US$/TEU #flows of containers

=3.14 US$/TEU #numbers on berths

Declaration of IP

Now we think we don’t use any closed IP owned by someone else. We have referred and researched just existing information

and they are open to everybody. Now we propose the innovated systems of which origin belongs to us.

Key Performance Area KPI

Performance

・Container Throughput

More than 20 million TEUs/annum #flows

More than 40 million TEUs/annum #numbers

・Theoretically

288,000*365=105million TEU/annum on berths

・Berth on Arrival

100% (including outrigger quays)

Berth within 1hr or ( 0.5 hr for feeders) on canals

Refer the section “Loading/Unloading”

Productivity

・Labor Productivity

2,984 persons

・Number of labor Hours per year per TEU

(320+20+136+80+50+20+120)*24*365/20millionTEU

=0.327hours/yearTEU (flows of containers)

=0.1635hours/yearTEU (numbers on berths)

・Land Productivity

85hectares (including outriggers)

230,000TEU/85hectares=2,700 TEU/hectare

Storage Capacity is 230,000TEUs(115,000 cells)

Sustainability

・Environmental Sustainability

Total energy consumption per year

=190 million(kwh/year)

Energy consumption per year per TEU

= 9.5 (kWh/year*TEU) #flows

= 4.75 (kWh/year*TEU) #numbers

Renewable energy generated on-site is

4.6 million(kwh/year)

Basically all energy will be generated on-site

by 4 gas-engines

・Financial Sustainability*

Total capital expenditure = 4.5billion (US$)

Now we assume the depreciable period is 20 years

(of course service life is more than 50 years)

Capital expenditure per TEU (flowing number)

=4.5billion/20million/20years

=11.25 (US$/TEU)

Operating expenditure

6.6+119 =125.6 million (US$/year)

Operating expenditure per TEU (US$/TEU)

125.6 million/20million

=6.28 (US$/TEU) #flows

=3.14 (US$/TEU) #number